Through the years, Edson has made a name for itself as the highly automated, go-to case packing system that nearly all major converted paper and diaper manufacturers around the world rely on. But, the brand is not just for those big guys anymore.

Today, the company offers case packing solutions designed for small to midsize companies that recognize how automation can help their end-of-line packaging operations as well.

The value Edson brings to these companies is flexible packing solutions that can adapt as their business grows in the future. While a fully automatic case packing system is likely not needed for many of these smaller applications, there are areas of the packaging line where automation does make sense and shows a strong ROI. So, with these adaptions moving into the market, there may be no better time to consider adding automation than right now.

Everyone seems to be experiencing staffing challenges because of the ongoing labor shortage. This hits especially hard for some of those smaller to medium size companies that traditionally have relied on manual end-of-line packing operations. In the past this strategy has suited them well as their production rate tended to be on the slower side, allowing hand-packing to handle the workflow. But, with employees at a premium for the past two years, finding enough workers to build, pack and ship cases has been troublesome.

Furthermore, the rise of e-commerce sales, increased SKUs, smaller case sizes and changing consumer buying preferences are collectively adding newfound pressures to companies’ packaging operations. These challenges are driving organizations to explore how automation can either augment or revamp their existing packaging processes.

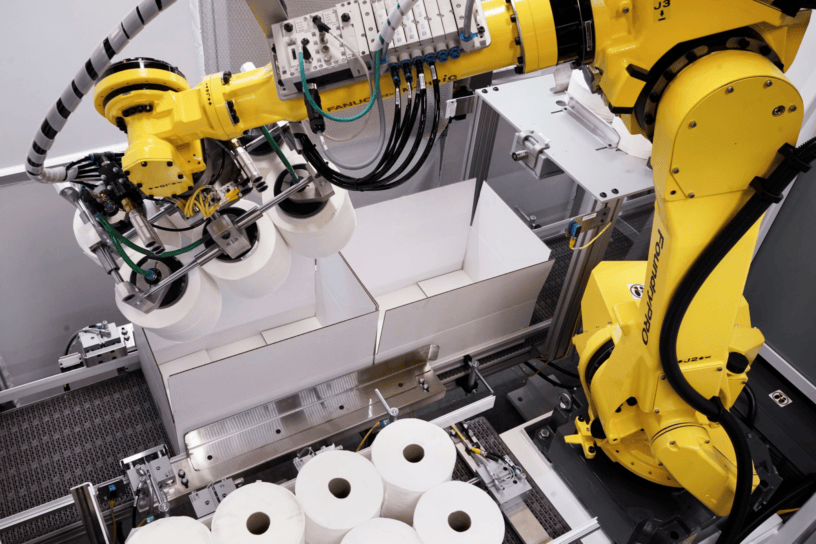

A new solution from Edson is its 4000TL Robotic Top Load Case Packer, which is designed as an entry-level machine for customers who are looking to add automation into their end-of-line packaging. The 4000TL, a machine conceived with simplicity in mind, does not require much adjustability and addresses many challenges small to midsize businesses are facing today, including staffing. The advantage of installing an automated case packer is that it reduces the number of employees that were previously staffing hand-packing lines. Those workers can be redirected to more critical positions within the company, leaving the more monotonous packing tasks to the automation system.

The machine can also handle multiple SKUs and pack patterns. Manufacturers, co-packers, and boutique suppliers may be running several SKUs in a day and typically do not require high packing speed to accomplish those runs. The 4000TL is perfectly suited for these types of applications as changeovers can be easily completed in less than 15 minutes.

Almost every packaging application can benefit from automation. Whether a brand is new to the market or more mature and looking to expand, Edson can evaluate applications and give specific recommendations that will help customers thrive in today’s ever-changing retail environment.

Susan Marshall is the General Manager at Edson. She can be reached at susan.marshall@promachbuilt.com; https://www.edson.com/.

Leave a Reply